REMOTION® BLUE is made from specially engineered polyester derived from ocean-bound plastic bottles, a premium raw material. This plastic is verified through Prevented Ocean PlasticTM, a global recycling initiative which helps tens of thousands of people around the world to earn their living, clean their coastlines and prevent ocean plastic.

Also available, REMOTION® GREEN made from domestic recycled plastic bottles.

The choice of a sustainable path

PREVENTED OCEAN PLASTICTM

Discarded plastic bottles are picked up by plastic collectors from areas at risk of ocean plastic pollution. The bottles are then taken to local collection centres for payment. Upon arrival the plastic bottles are sorted and then pressed for transport to plastic recycling factories. At the factory, the plastic is washed, sanitised and processed into raw material flakes or pellets, all according to European and North American quality standards.

REMOTION® for apparel textiles with high performance attributes combined with ocean friendly sustainability.

Both REMOTION® BLUE and REMOTION® GREEN are OEKO-Tex certified.

And eligible for GRS (Global Recycled Standard) certification.

Biodegradable

Biodegradable

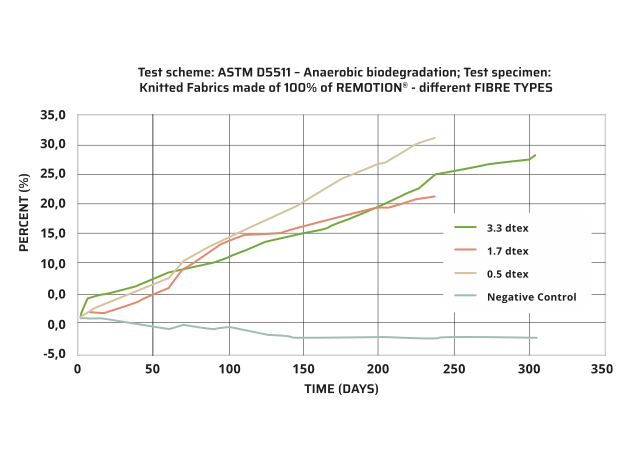

REMOTION® can be recycled in the same way as standard polyester. In addition, to reduce the risk of plastic and microplastic pollution in marine and land environments, biodegradability of REMOTION® is achieved by using an additive that allows microbes like bacteria and fungi to settle on the fibre surface and break down the polymer structure without producing harmful or noxious residues. During biodegradation, the final decomposition product is biogas, carbon dioxide and methane.

REMOTION® can be recycled in the same way as standard polyester. In addition, REMOTION® is expected to biodegrade 30 to 40 % within a year* and approximately 90% within 4 years in marine environments. This is reducing plastic pollution and potential microplastic pollution caused by fibre shedding in wastewater after apparel laundering. Learn more

* Degradation rates strongly depend on individual factors like temperature, moisture, surface area and exposure of final article in the soil, types of microorganisms etc.

Moisture Management

Moisture Management

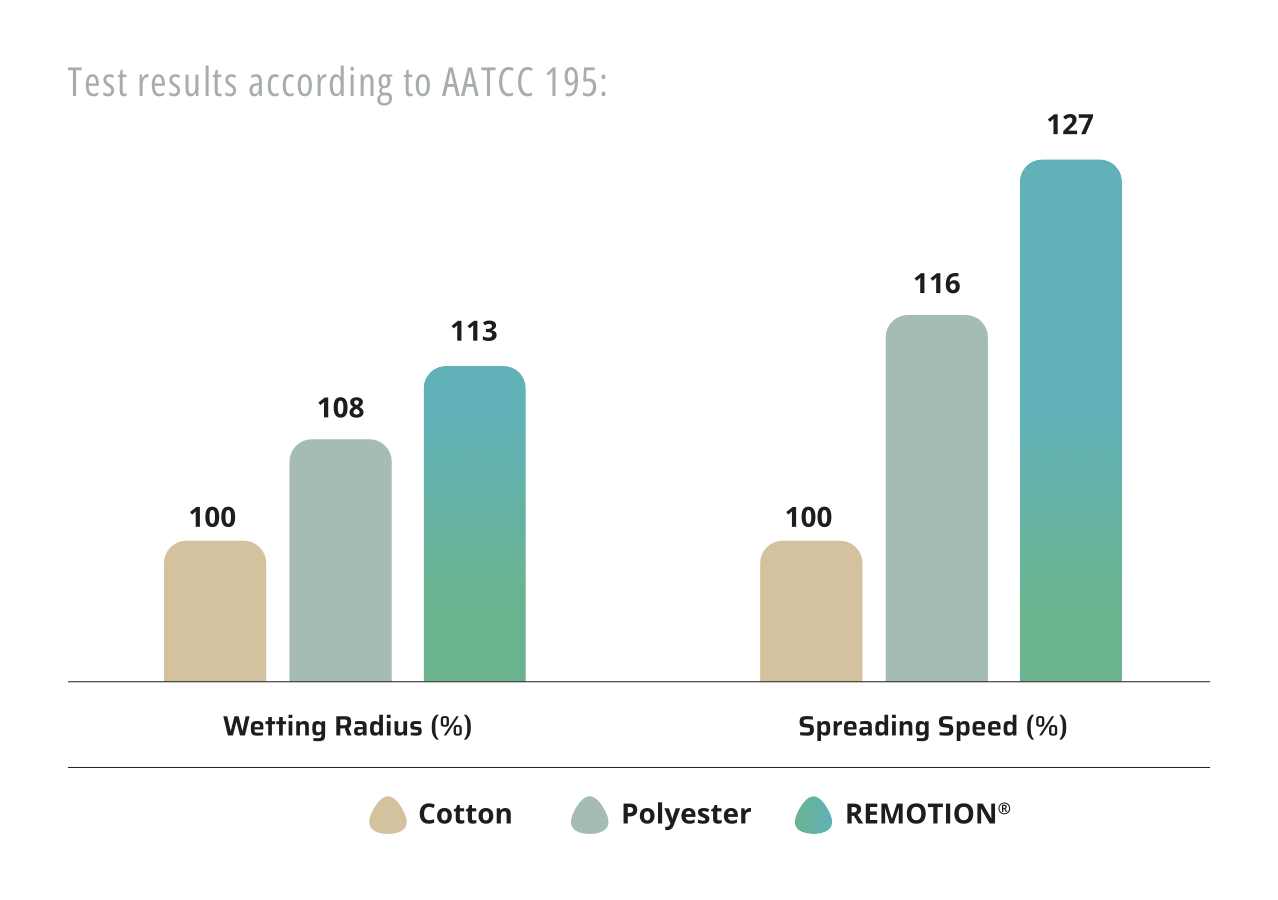

The unique modified cross section more then doubles the surface area of each filament compared to standard polyester. The multichannel structure creates a capillary system allowing fast moisture distribution within the fabrics and faster evaporation for better temperature regulation.

The capillary system in the fabric allows the humidity to be transported away quicker compared to other fabrics. This helps to keep the body dry and cool for a longer fresh feeling, even after numerous washes. The excellent moisture management properties of REMOTION® have profound impacts on clothing performance as well as on wearing comfort.

Anti-Bacterial

Anti-Bacterial

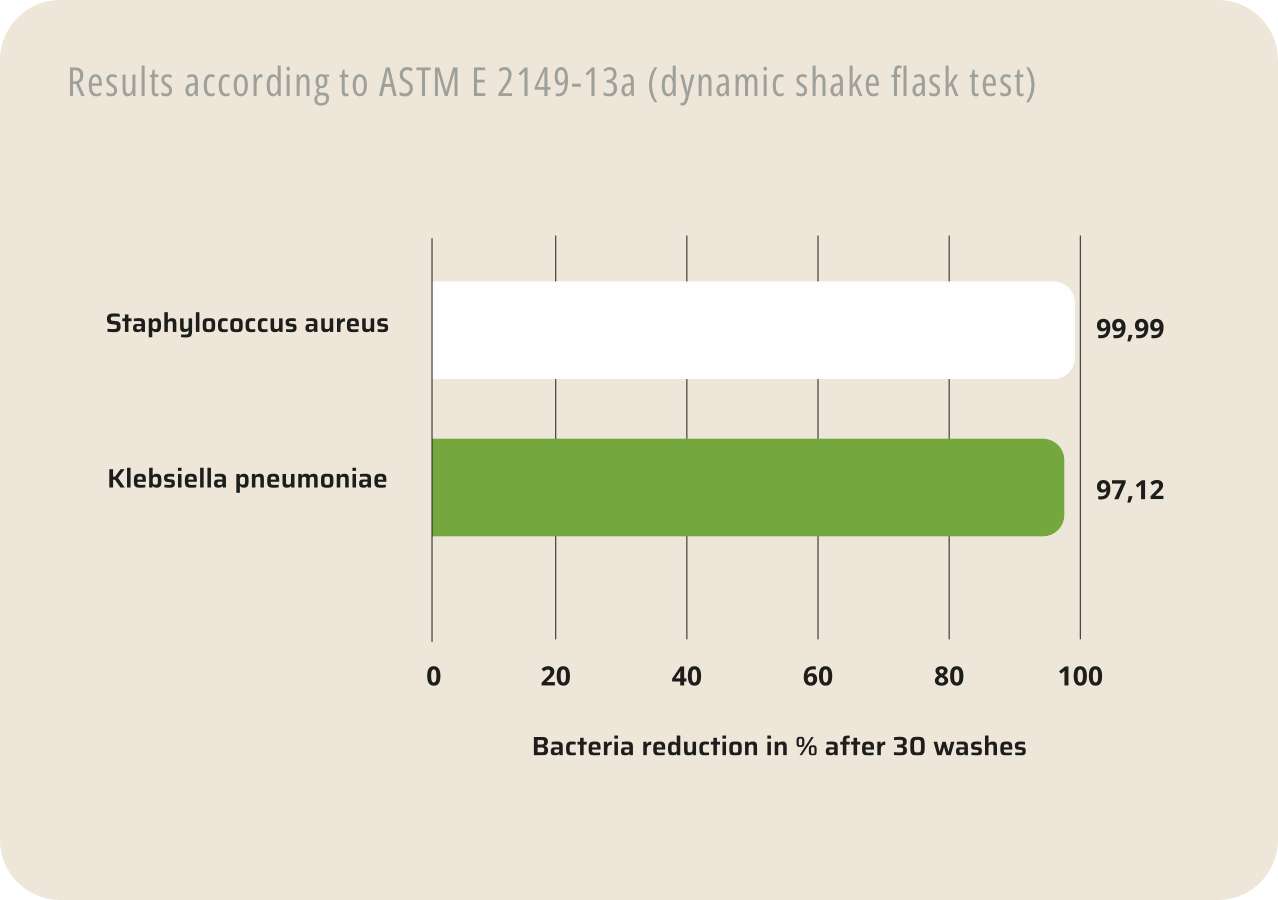

The polymer is modified with Quat-Silane molecules which creates a kind of microscopic needle on the surface. As a microbe comes in contact with that surface, it will be electrically neutralized. REMOTION® does not contain any silver ions.

Excellent antibacterial properties are achieved by Quat-Silanes which are durable, non-leaching, persistent and antimicrobial, effective against a wide range of unicellular microorganisms.

The antibacterial property suppresses the growth of bacteria on the fabric, creating anti-odor benefits.

Coloured

Coloured

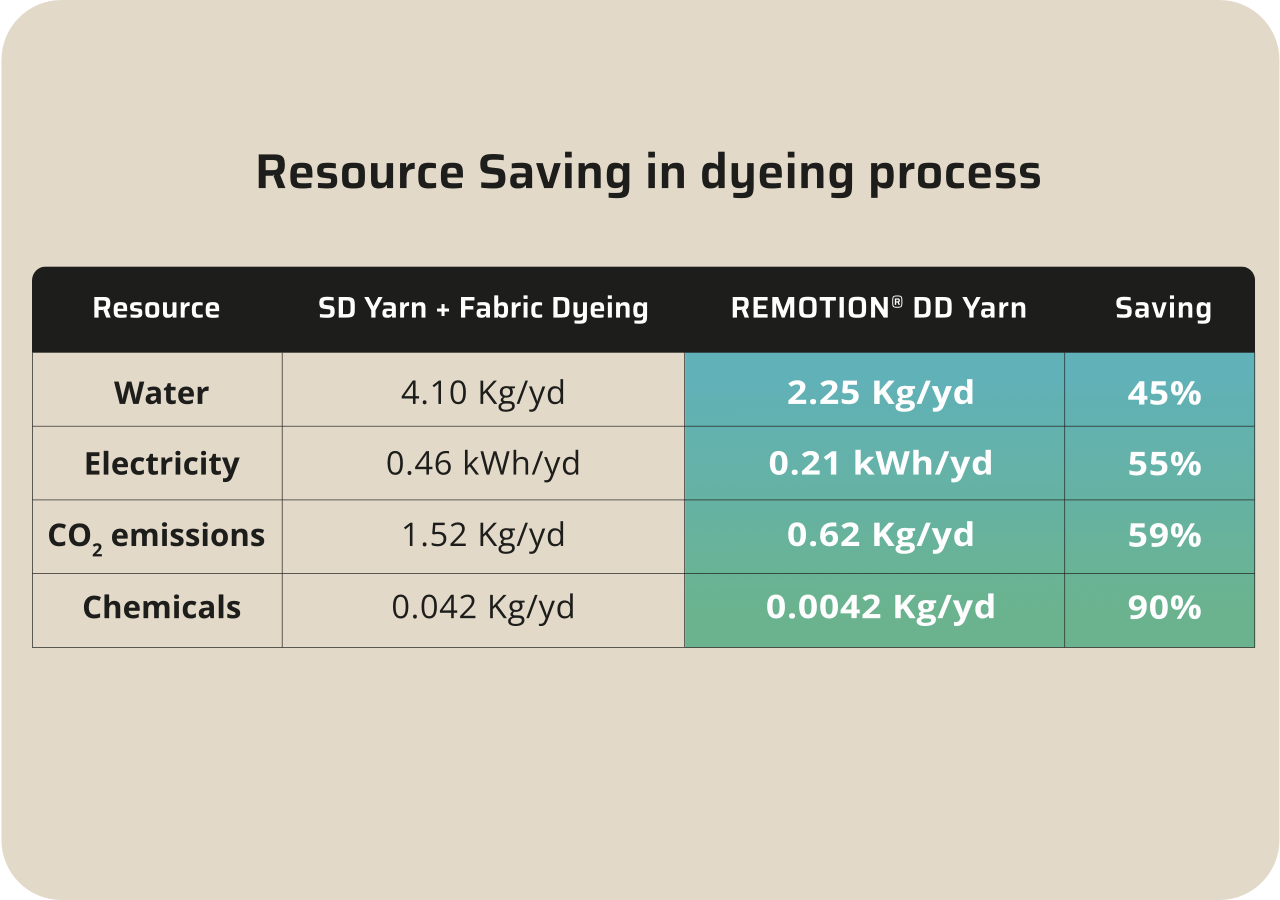

Dope dyeing (also called solution dyeing) is done with direct introduction of dyestuff into the melted polymer during the filament spinning process.

The coloured hot mass is pressed though the spinnerets and filaments are formed where no additional cleaning process is needed.

Dope dyeing is a more sustainable process using less water on average, less chemicals, less energy and less CO

It also delivers high color fastness for long-lasting usage.

Compared to conventional dyeing process, dope dyed REMOTION® makes the production costs of textiles more attractive.

REMOTION® Blue High insulation

REMOTION® Blue High insulation

The 40% high void content of REMOTION® Blue fibre creates a unique air pocket system within the insulation wadding. Unique combination of spiral crimp with special finish is delivering softness and durability.

High insulation performances with low weight are achieved by the high air content trapped in the fiber and within the insulation wadding system.

Durability with no clumping is provided by the fibre unique structure associated with special crimp design.

The fibre is certified animal free.

Contact us for more information

Email Us

Call Us

Tel. +49 2388 3036 0